Explore Charvonia Design products

Product Filters

Shop Charvonia Design

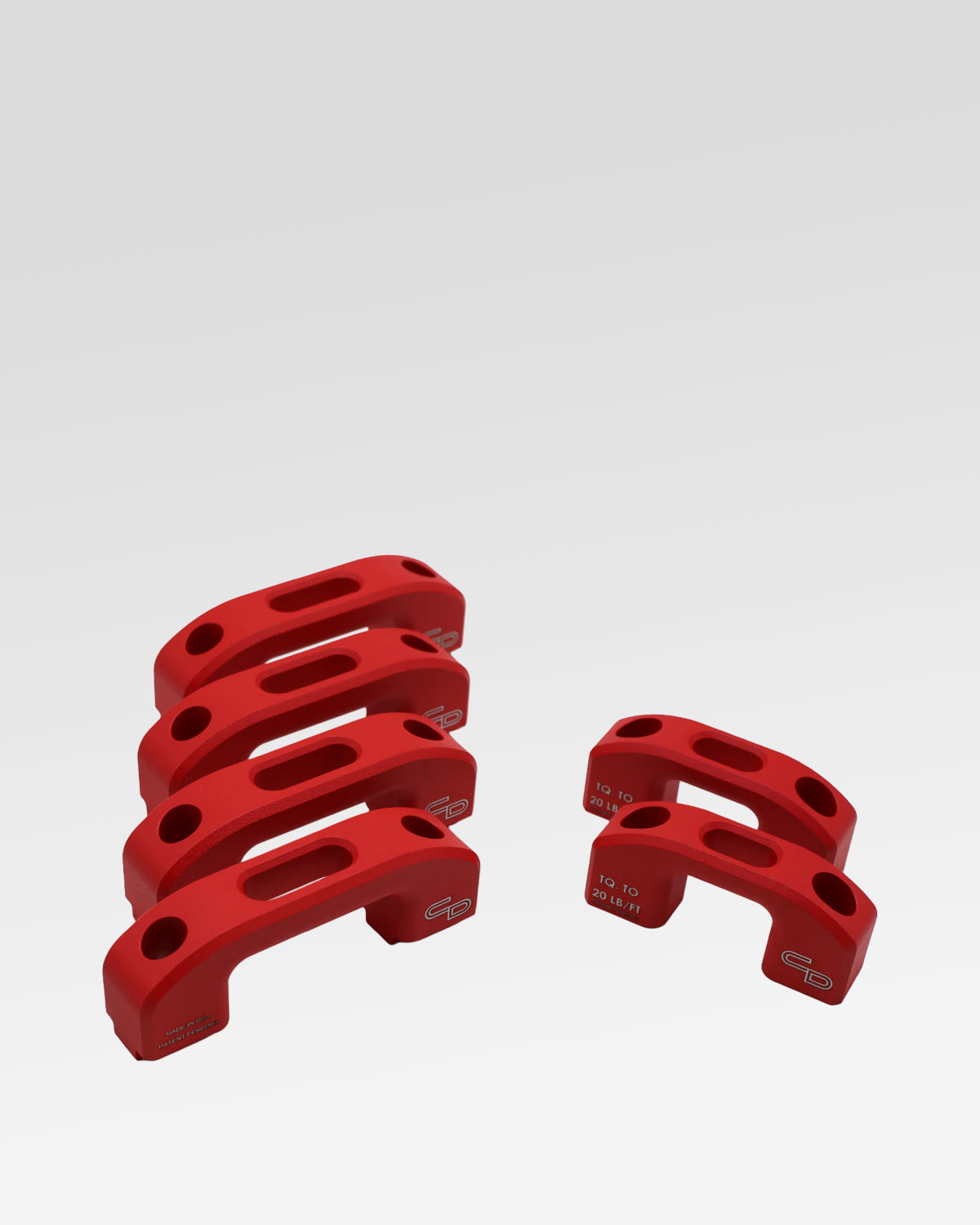

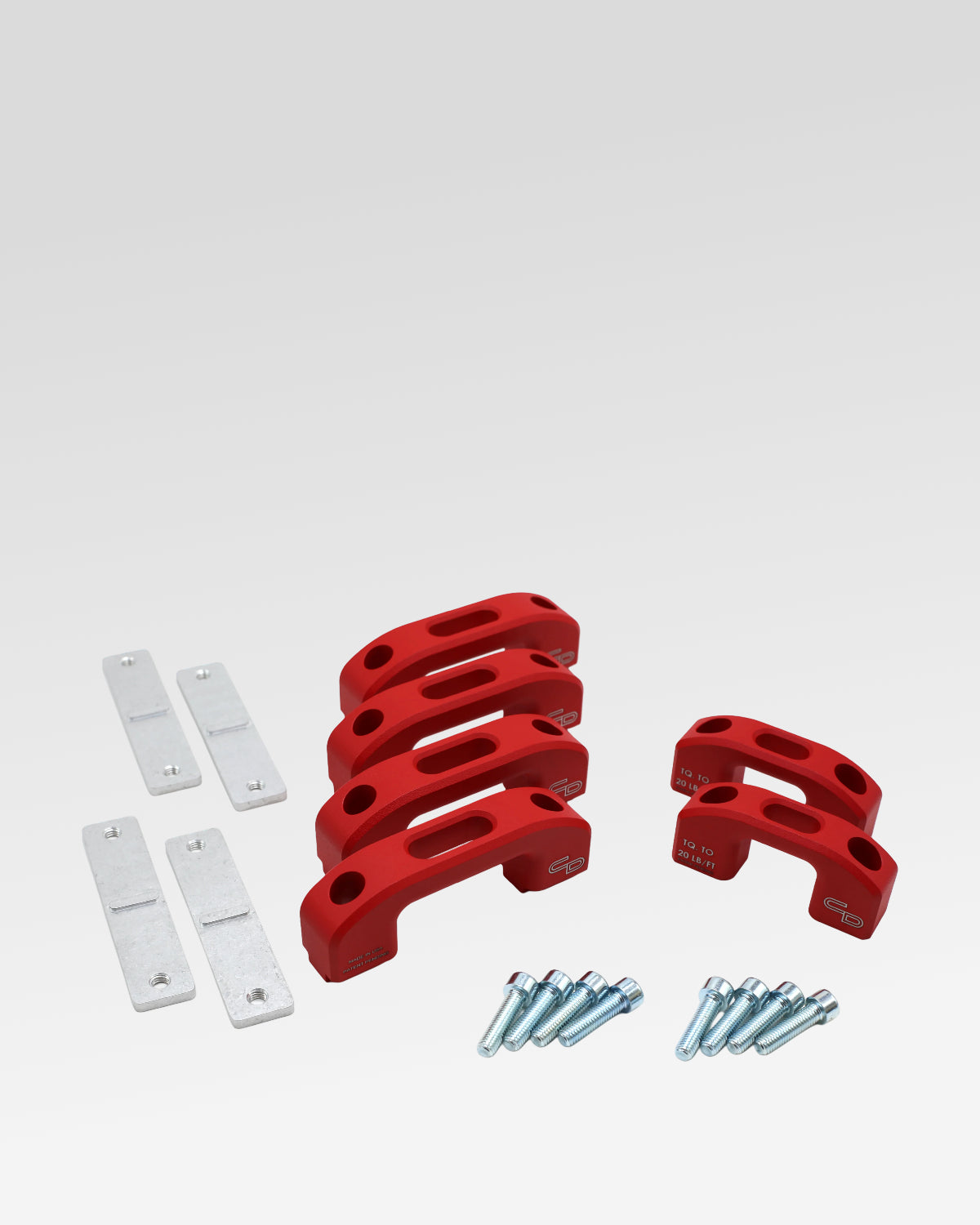

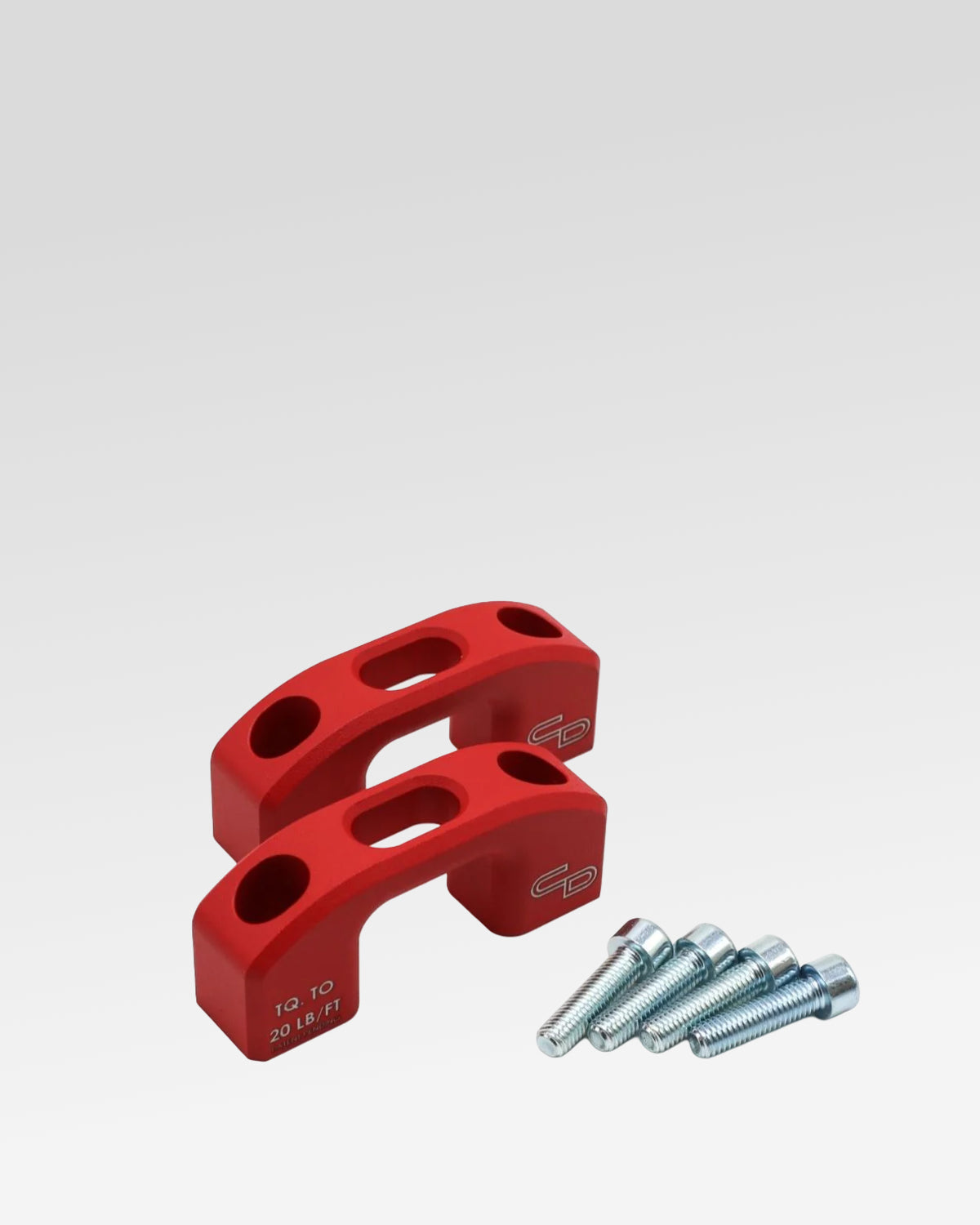

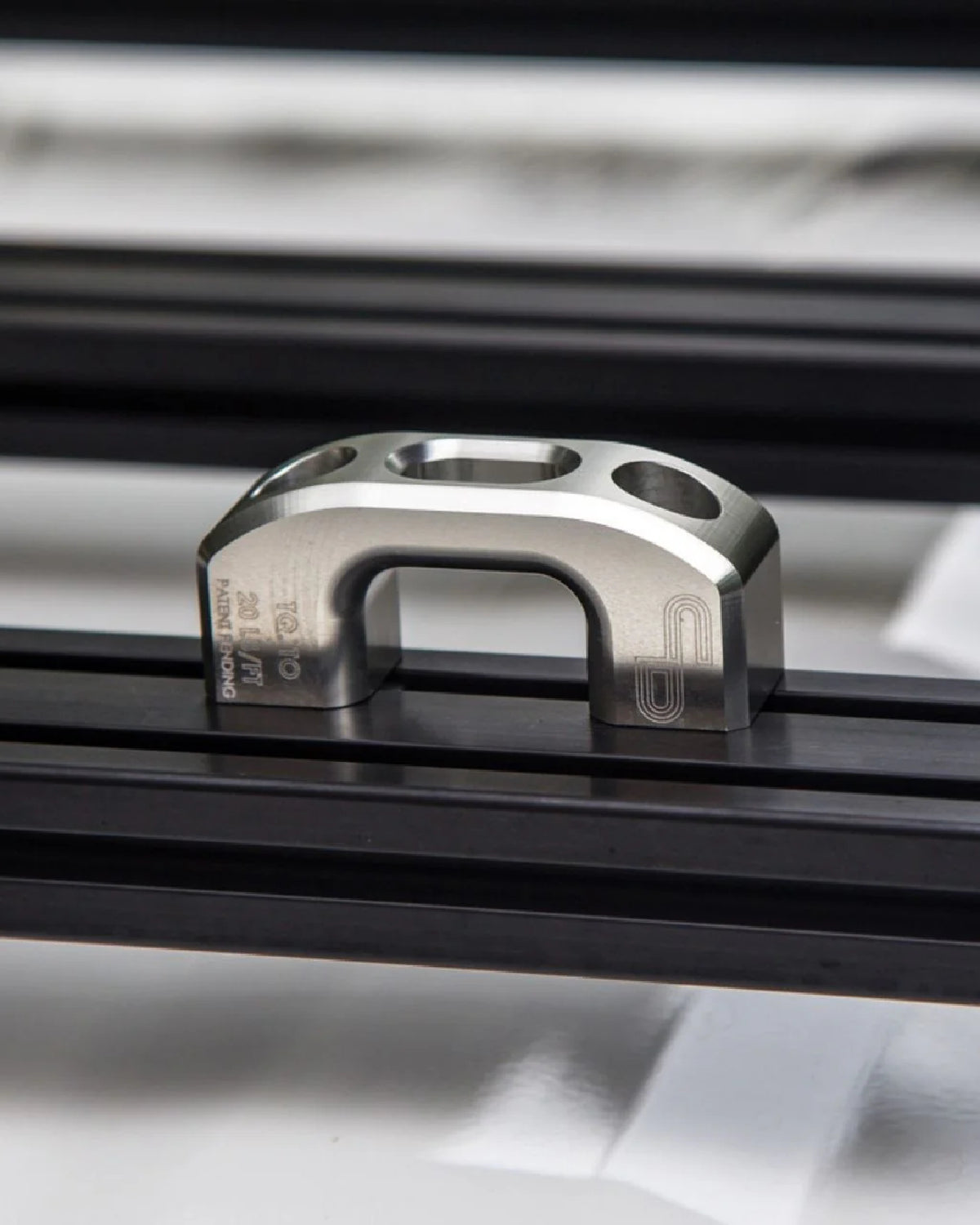

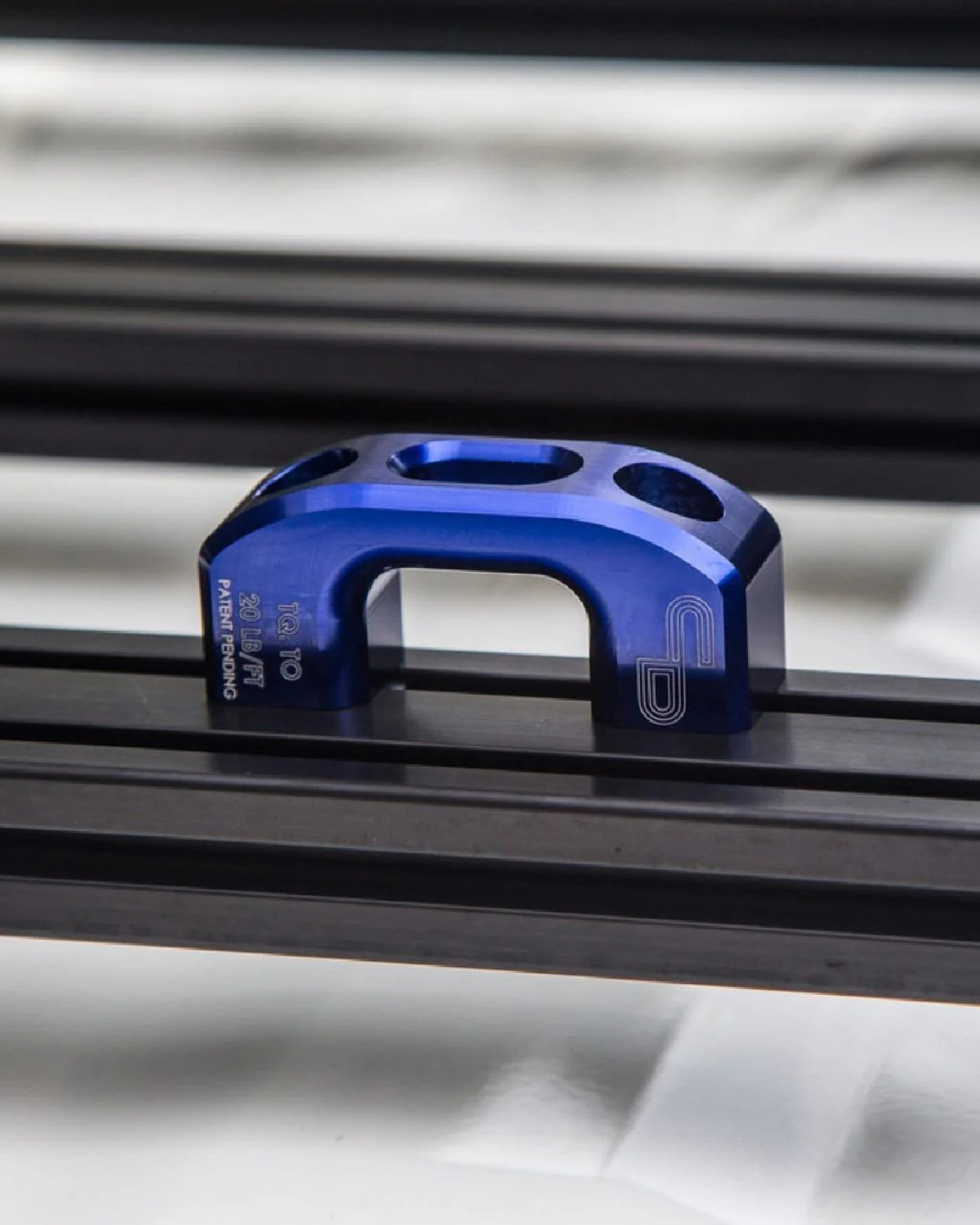

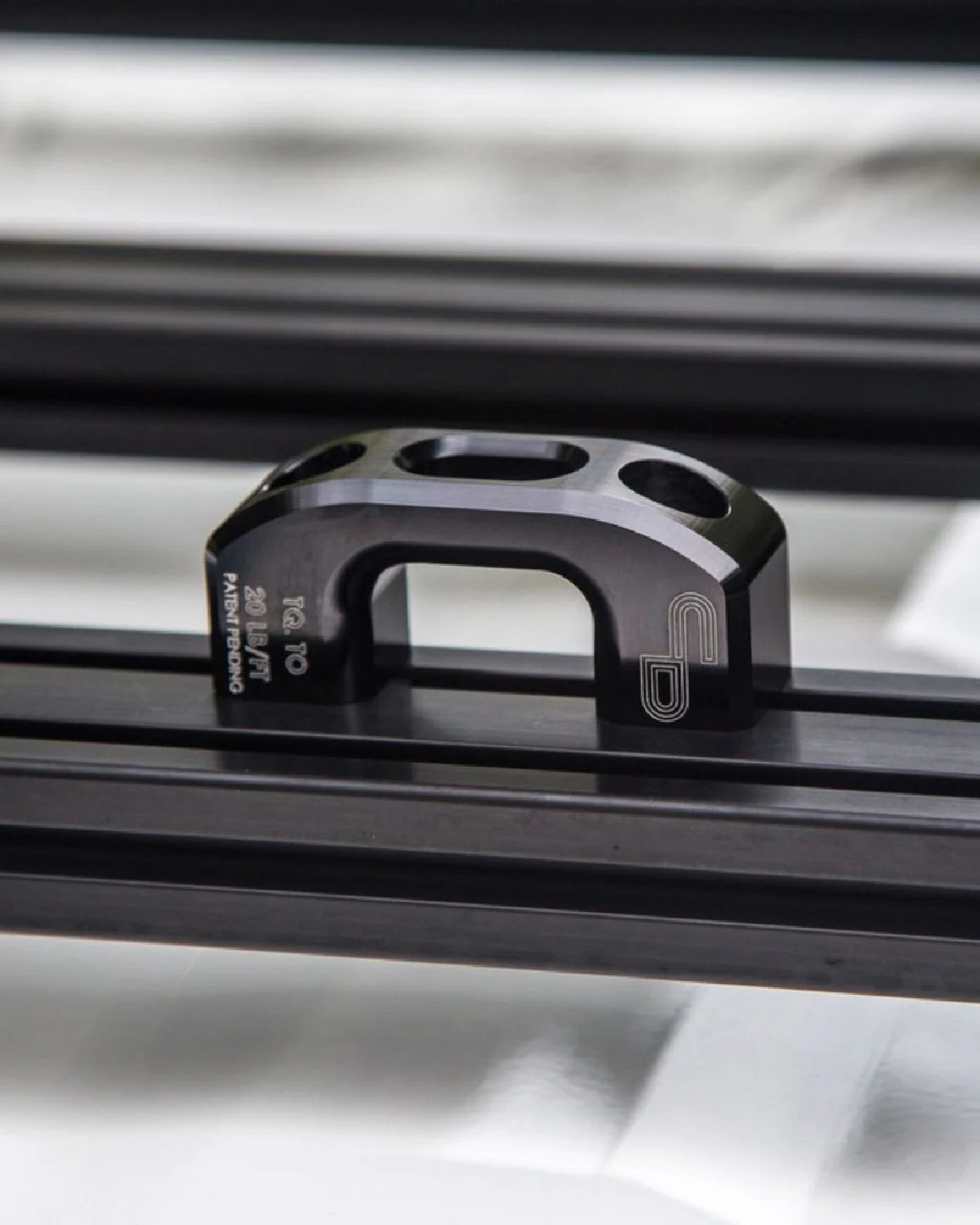

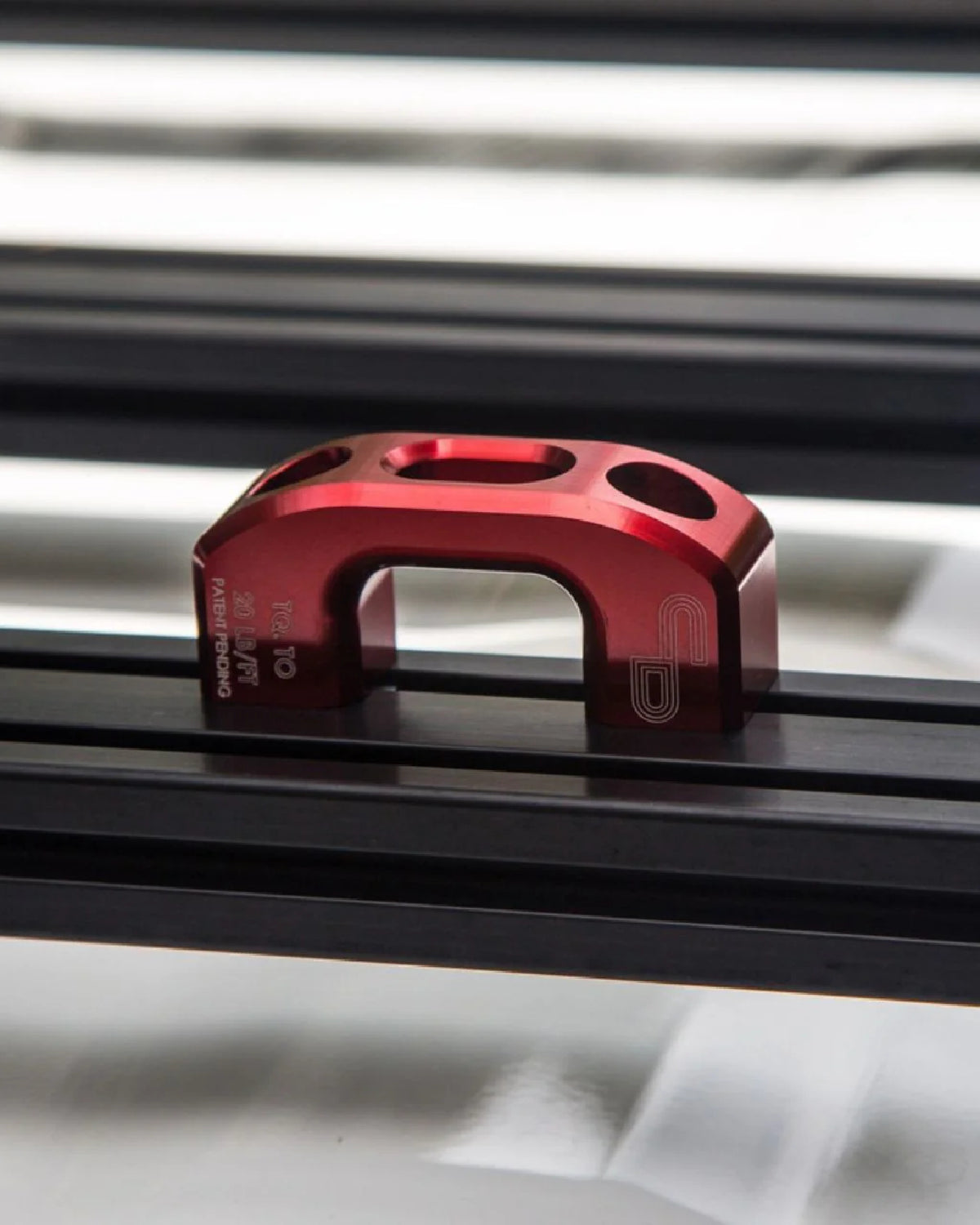

Charvonia Design components offer a professional-grade approach to securing cargo and accessories in high-demand off-road environments. Explore billet D-rings, tie-down anchors, and mounting points, all CNC-machined in the U.S. Built for serious truck bed users and overlanders, these parts bring confidence to load management while adding a refined, minimalist aesthetic to your setup.

Engineered Strength, CNC-Milled Accuracy

Every product is cut from high-grade aluminum blocks and precisely milled to deliver consistent performance in high-load scenarios. Anchor points feature beveled edges for strap preservation and hardware for ease of use in truck beds, roof racks, bed racks, drawers, and cargo trays. The hard-anodized finishes ensure long-term resistance against abrasion and oxidation, even in desert, alpine, or coastal environments.

Trusted by Off-Roaders Worldwide

These tie-down systems and cargo solutions are frequently integrated into SEMA-grade builds, expedition prep rigs, and high-utility field vehicles. Whether you’re building for looks, load security, or long-distance functionality, this collection reflects the discipline and performance that Charvonia Design is known for: American-made, overbuilt, and unapologetically precise.